Beyond Foam: The Rise of Non-Melt Spacer Fabrics in Aircraft Seat Construction

As aircraft interior programmes place increasing emphasis on fire safety, heat release and smoke density performance under FAR/CS 25.853, attention is turning to a component long considered standard: polyurethane foam within seat construction.

A new generation of flame-retardant 3D spacer textiles is now challenging that default.

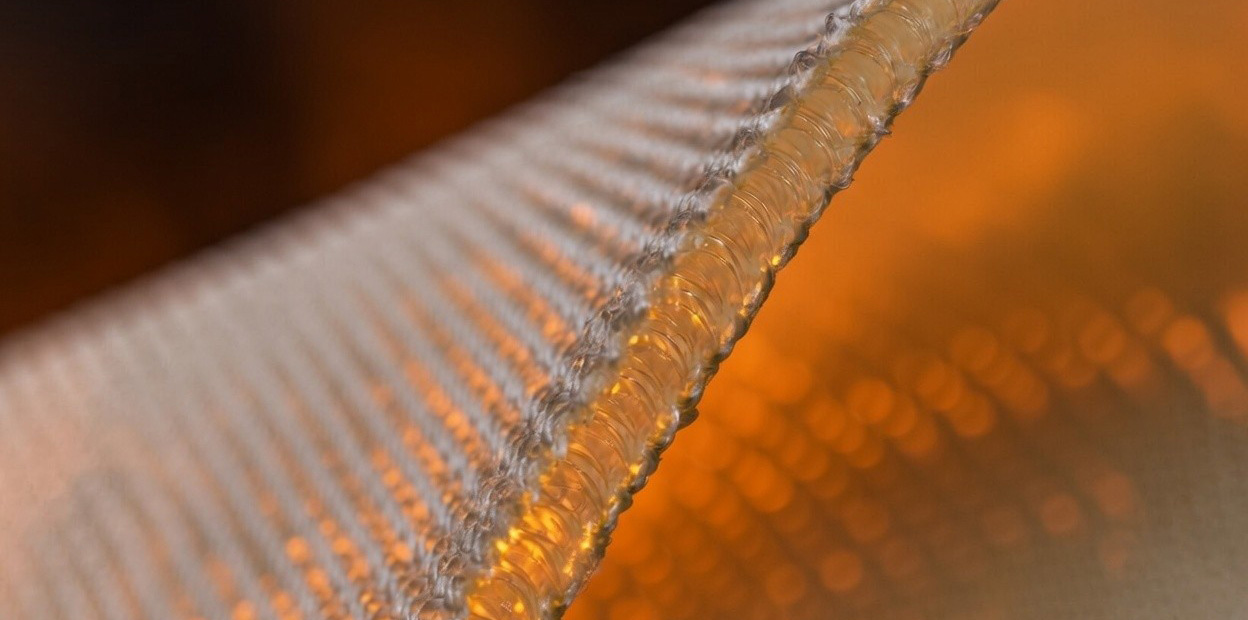

At the forefront is EVO-FR™, a PEI-based 3D knitted spacer fabric engineered specifically for aircraft seat applications. Unlike conventional foams, which can melt, drip and emit dense smoke when exposed to flame, EVO-FR™ exhibits non-melt, non-drip behaviour. Under heat, the material degrades and carbonises, helping reduce smoke density while maintaining structural integrity.

Redefining Material Assumptions

“Foam has been widely accepted for decades, but with EVO-FR™, we’re introducing a flame-retardant spacer textile that behaves fundamentally differently under heat,” says Gemma Groves, Knitting Sales Manager at Heathcoat Fabrics Ltd. “In a confined aircraft cabin, reducing melt-drip and smoke generation can make a measurable difference.”

Polyetherimide (PEI) is already trusted in hard aircraft interior components, including galleys, partition liners and ceiling panels. Its processing into a compressible 3D knitted spacer textile format marks a new application within soft furnishings and seat construction.

Part of the Spacetec® family

EVO-FR™ forms part of Heathcoat Fabrics’ Spacetec® family of 3D spacer fabrics, developed as alternatives to foam beneath leather or synthetic upholstery, within dress covers and across vertical cabin surfaces. Thickness options range from 2mm to 6.5mm, with capabilities to knit up to 10mm, enabling use across multiple seating classes and cabin zones.

The development is supported by vertically integrated manufacturing. Heathcoat Fabrics combines warp knitting, weaving, dyeing, finishing and technical testing within its UK facility, enabling full material traceability and controlled quality assurance – essential for aerospace qualification.

“In aerospace, innovation must be repeatable and fully documented,” Groves explains. “Because we control the process from yarn through to finished textile and testing, we can ensure compliance, consistency and complete traceability.”

Burn performance – inherent, not applied

The performance of EVO-FR™ is inherent to the polymer itself rather than applied as a secondary treatment. The material is being developed to meet vertical burn, heat release and smoke density requirements under FAR/CS 25.853, with further certification progressing.

Beyond fire performance, spacer textiles offer durability advantages over foam. Where open-cell foams can compress permanently or degrade over time, spacer fabrics retain form and regain, delivering more predictable comfort and potentially extending service intervals.

Heathcoat’s patent-pending PEI-based EVO-FR™ spacer textiles are positioned as a credible successor to foam in aircraft seating – offering a fundamentally different fire-response profile in one of the cabin’s most established material systems.

Contact spacetec@heathcoat.co.uk for further information.